HUMANS AND MACHINES TRANSFORMING YOUR BUSINESS, TOGETHER

collaborative and effective for every application

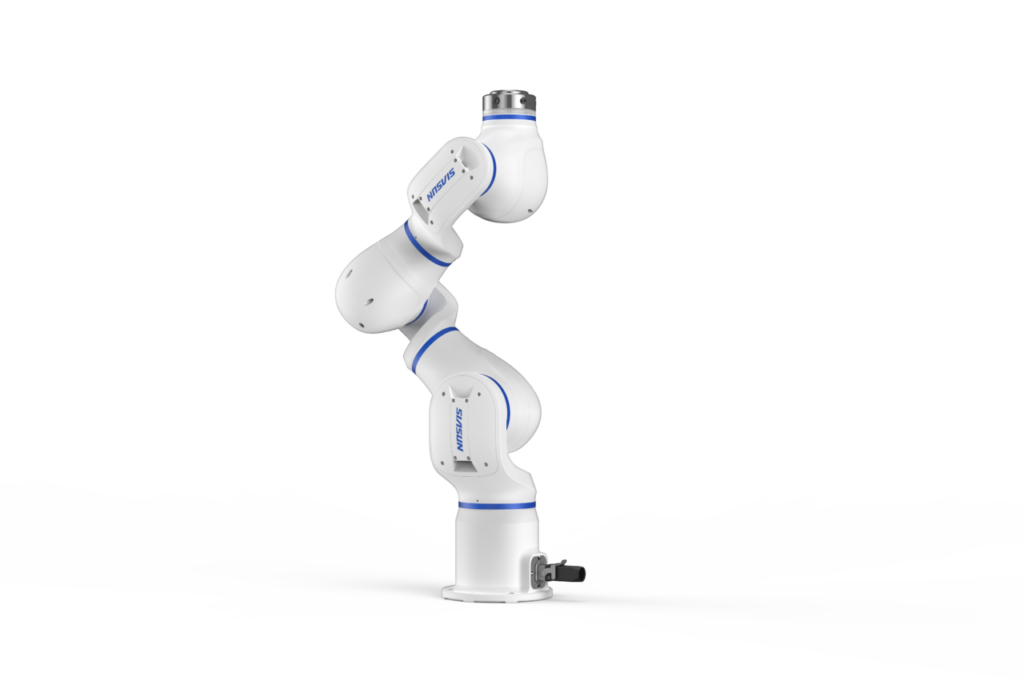

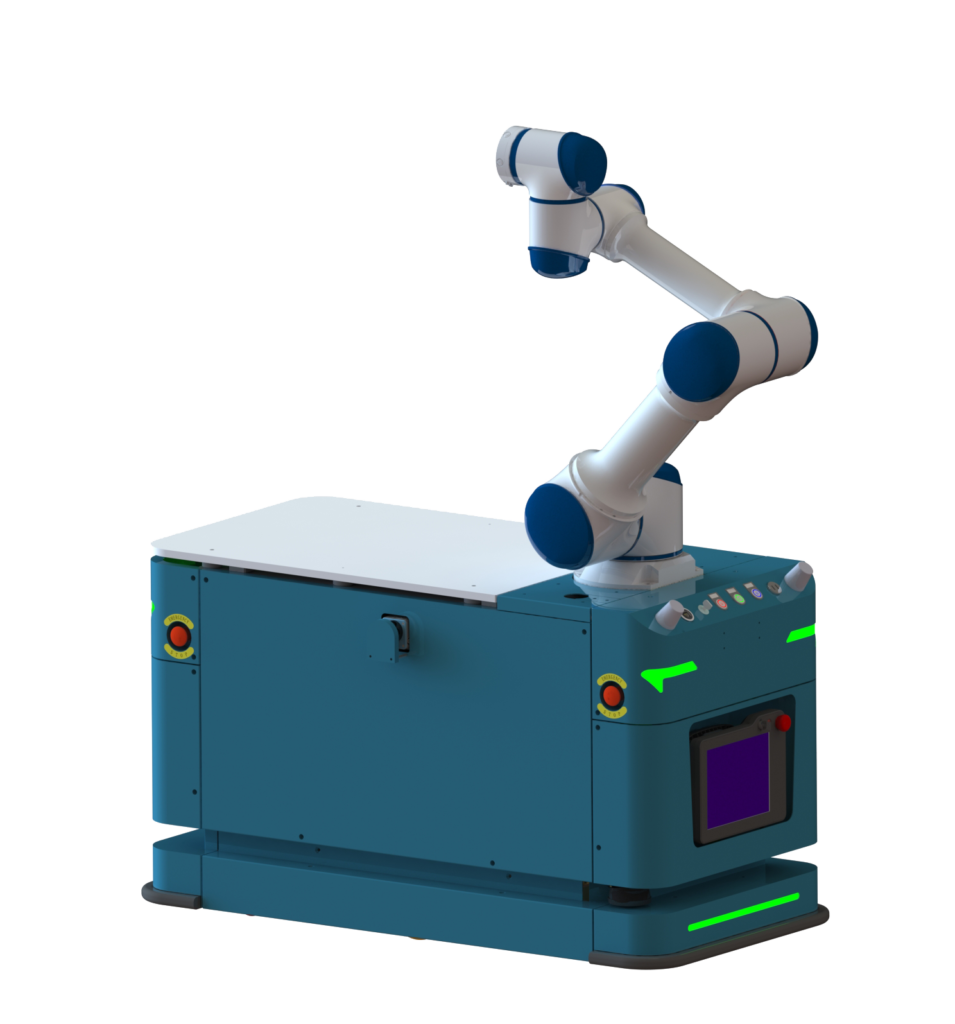

Collaborative robots (cobots) work in conjunction with humans, assisting them safely and effectively. They can be mobile multitaskers, small and lightweight, moving between areas of the manufacturing floor and, when in their new position, quickly switch between tasks thanks to their intuitive GUIs.

In addition, the range of applications for cobots is growing in other industries beyond manufacturing, such as agriculture, food service, life sciences, consumer goods, plastics, and electronics.

Cobots aren’t designed to remove human workers from jobs entirely but to integrate into the portion of repetitive and dull jobs that could risk errors or injury because of human operators losing focus.

Additionally, because cobots tend to be small and dexterous, they are ideal partners when the task is fiddly with small parts or involves intricate placement, the type of job performed at a workbench.